Industrial Metal Detectors

Metal Detection Equipment

Tectron Engineering is one of the leading manufacturers for industrial metal detectors and metal detection equipment. Our line of industrial metal detectors included, but is not limited to, conveyor belt metal detectors, inline metal detectors, feeder metal detection, high sensitivity mental detection, and pulse metal detection equipment.

Industrial Metal Detector – Model 100

Economical Metal Detection Equipment for detecting large metal

The digital Model 100 detector has an economical design for applications requiring detection of bucket teeth and other large pieces of metal. The model 100 is pre-fabricated to fit CEMA standard conveyors in belt widths up to 48”, and the aperture can be field adjusted to handle most standard application requirements. The model 100 replaces the analog model T2000 detector sold for many years.

Industrial Metal Detector – Model 50

Rugged, Reliable Mid-Range Metal Detection Equipment for difficult applications

The digital Model 50 detector is the most commonly used detector in our product line. The combination of high sensitivity and flexibility make the model 50 ideal for a wide variety of applications. The model 50 can be tuned to ignore conductive and even magnetic ores such as pyrite and magnetite, even if they are carried by high tension steel cord belts with rip detection loops, and is still able to detect small pieces of metal. The model 50 is available in nearly any belt width, and can be field adjusted to fit most standard conveyor configurations. The model 50 replaces the models 5000, 8000, and 8600 detectors sold for many years.

Industrial Metal Detector 5500 E1

High Sensitivity Metal Detection Equipment for mining & aggregate

The model 5500 E1 metal detector is engineered to be the most sensitive detector on the market for installation on conveyor belts carrying coal, minerals, aggregates and other bulk materials. The model 5500 E1 can be tuned to ignore conductive ores such as gold, copper or zinc while still detecting small pieces of tramp metal. The model 5500 E1 is available in nearly any belt width, and is factory customized to fit your conveyor. The modular design makes the model 5500 E1 easy to install without the use of special tools or the need to cut the belt, while the field replaceable electronics are easy to operate and maintain. With thousands of units installed worldwide, the model 5500 E1 has proven to be reliable and durable.

Industrial Metal Detector 5500 E6

High Sensitivity Metal Detection Equipment

The model 5500 E6 is engineered to be the most sensitive pulse induction metal detector available. The 5500 E6 is typically used in food, glass and plastic recycling, wood chips, and pulp paper applications which demand the highest possible sensitivity while remaining immune to moisture, salt and other product effects. The 5500 E6 can be built to nearly any belt width and is factory customized to fit your conveyor. The modular design makes the 5500 E6 easy to install without the use of special tools, or the need to cut the belt, while the field replaceable electronics are easy to operate and maintain. The 5500 E6 is the model of choice for applications requiring the highest sensitivity and trouble free operation.

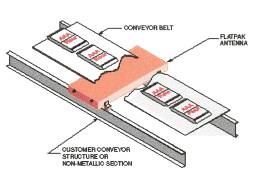

Industrial Metal Detector 50 Flat Pack

Under Conveyor Metal Detection Equipment

The same rugged design and flexibility of the model 50, but in a detector that fits entirely underneath the belt. Used in applications with low burden depths, below 6” (150mm) recommended, or applications where the metal contamination is always positioned very close to the surface of the belt. The simple design is easy to install and can be customized to fit the conveyor.