Mining Metal Detection Equipment

Mining Metal Detection Equipment

In the mining industry, Tectron Metal Detectors are used to protect crushers, belts and other downstream equipment from tramp metal contamination. The metal to be detected varies widely based on the specifics of the equipment being protected. For example, a cone crusher with a 1” gap can pass ½” metal without causing a problem, but a 1.25” piece of metal will likely cause some damage. In underground mining, roof bolts can become mixed in with the product and spear and tear belts at transfer points. Clients should also consider the types of metals commonly found as contamination. Digger teeth from front end loaders and wear plates from crushers are commonly made of high manganese steel which cannot be lifted by a magnet, and can be more difficult to detect than other forms of mild steel. Gathering data like the frequency of tramp metal contamination (number of pcs per day/week/month) the type of metal, and the shape of metal can all help to define the problem, and are very useful in choosing the right solution. When lost production time is considered, the ROI on a Tectron Metal Detector is usually achieved when the first piece of tramp metal is stopped.

Mining & Aggregate Metal Detectors

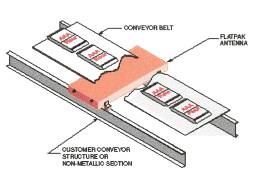

The Tectron® model 100, when installed on a conveyor system, provides protection to downstream processing mining equipment by detecting the presence of potentially damaging metal objects.

The Tectron® Model 50 is engineered for installation on conveyor belts carrying coal, minerals, aggregates, and other bulk materials related to mining.

The Tectron® Model DMD 25 is engineered to be the most sensitive metal detector on the market for installation on conveyor belts carrying coal, minerals, aggregates, and other bulk materials related to the mining industry.

This unit is a single antenna mounted underneath the conveyor belt. It is best suited for those who require nothing above the conveyor belt because the material being conveyed is odd shaped or of varying height and where the metal is lying on or close to the belt.

Used specifically for iron ore in the mining industry. The Model 8050 has the unique ability to detect and discriminate between non-magnetic & magnetic, tramp metals.